Thermal management of the tooling and dies is a critical production factor in

quality die casting.

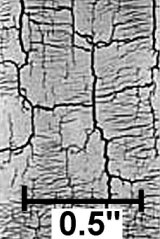

a casting

run, "heat checking"

can occur.

Heat checking is the

formation very fine surface cracks on the die faces, which will transfer to the die

casting as raised veins

on the surface..

The die casting engineer has to consider the thermal loads that occur in

production (in terms of the thermal mass and the cycle rate) and ensure that the die

faces do not overheat. |

|

Heat

Checking

on a Die Face |

|